When it comes to identifying the strongest metal, many people are intrigued by which material truly excels in terms of strength, durability, and versatility. Whether you're an engineer, scientist, or simply someone fascinated by metallurgy, understanding the properties of metals is essential. This article provides an in-depth exploration of the strongest metals, analyzing their characteristics, applications, and importance in modern industries.

Metals have played a critical role in human civilization for millennia. From ancient tools and weapons to modern infrastructure and cutting-edge technology, metals continue to shape our world. Among the diverse range of metals available, some stand out due to their exceptional strength and durability. Determining the strongest metal isn't just a matter of curiosity; it's a critical factor for industries that rely on reliable materials for construction, aerospace, and other demanding fields.

This article will delve into the concept of the strongest metals, discuss their properties in detail, and examine their practical applications. Whether you're searching for a material capable of withstanding extreme conditions or simply aiming to expand your knowledge of metallurgy, this guide will equip you with the information needed to make well-informed decisions.

Table of Contents

- Understanding the Strongest Metal

- What Constitutes the Strongest Metal?

- Leading Contenders for the Strongest Metal

- Key Properties Defining the Strongest Metal

- Titanium: The Lightweight Giant

- Tungsten: The Metal Unmatched in Hardness

- Steel: The Backbone of Construction

- Applications of the Strongest Metals

- Comparing the Strongest Metals

- The Evolution of Strong Metals

Understanding the Strongest Metal

Metals are categorized based on their distinct properties, such as strength, density, and corrosion resistance. Among these attributes, strength often takes precedence for various applications. The strongest metal is typically defined by its capacity to endure extreme pressure, temperature, and stress without deforming or breaking. This makes it an invaluable choice for industries that demand high-performance materials.

Why Strength Is Paramount

Strength is a crucial determinant in selecting metals for specific purposes. For instance, aerospace engineers require metals that can withstand the rigors of space travel, while construction companies need materials capable of supporting massive structures. Grasping the strength of metals enables engineers and scientists to make well-informed decisions when choosing materials for their projects.

What Constitutes the Strongest Metal?

The concept of the strongest metal can be examined from multiple perspectives, including tensile strength, hardness, and resistance to wear. Tensile strength refers to a metal's ability to resist breaking under tension, while hardness measures its resistance to deformation. Both properties are vital in evaluating the overall strength of a metal.

Factors Influencing Metal Strength

- Composition: The blend of elements in a metal alloy significantly impacts its strength.

- Crystal Structure: The arrangement of atoms in a metal's lattice structure plays a crucial role in determining its mechanical properties.

- Processing Techniques: Methods like heat treatment and forging can enhance a metal's strength, making it more suitable for demanding applications.

Leading Contenders for the Strongest Metal

Several metals are strong contenders for the title of the strongest metal. Each possesses unique properties that make it ideal for specific applications. Below, we will explore some of the top contenders for this prestigious title.

1. Titanium

Titanium is celebrated for its remarkable strength-to-weight ratio. Despite its lightweight nature, it offers exceptional durability and corrosion resistance, making it a favored choice in aerospace and medical applications. Its ability to withstand harsh environments while maintaining its integrity is unmatched.

2. Tungsten

Tungsten claims the title of the hardest metal on Earth, boasting a melting point exceeding 3,400°C. Its high density and strength render it perfect for applications requiring extreme heat resistance, such as light bulb filaments and cutting tools. Its unparalleled hardness ensures longevity and reliability in demanding conditions.

3. Steel

Steel remains one of the most extensively used metals globally due to its versatility and affordability. Its strength can be enhanced through alloying with other elements, making it suitable for construction, automotive, and industrial applications. Its adaptability and cost-effectiveness contribute to its widespread adoption across various sectors.

Key Properties Defining the Strongest Metal

The strongest metal must exhibit a combination of desirable properties, including tensile strength, hardness, and resistance to wear and corrosion. Below, we will delve deeper into these properties.

Tensile Strength

Tensile strength is a critical factor in assessing the strength of a metal. It measures the maximum stress a material can endure before breaking. Metals with high tensile strength are often utilized in applications where durability is paramount, ensuring longevity and reliability.

Hardness

Hardness refers to a metal's ability to resist scratching or deformation. Tungsten, for example, is renowned for its exceptional hardness, making it ideal for applications requiring wear resistance. This property ensures that the metal maintains its integrity even under extreme conditions.

Titanium: The Lightweight Giant

Titanium is often referred to as the "lightweight giant" due to its impressive strength-to-weight ratio. It is approximately 45% lighter than steel yet offers comparable strength. This characteristic makes it an attractive option for industries where weight reduction is a priority, such as aerospace and automotive manufacturing.

Applications of Titanium

- Aerospace Components: Titanium is extensively used in aircraft construction due to its strength and corrosion resistance, enabling the creation of lightweight yet durable structures.

- Medical Implants: Its biocompatibility and durability make titanium an excellent choice for medical implants, such as joint replacements and dental implants, ensuring long-term functionality and patient comfort.

Tungsten: The Metal Unmatched in Hardness

Tungsten is the hardest metal on Earth, with a melting point surpassing 3,400°C. Its high density and strength make it ideal for applications requiring extreme heat resistance and wear resistance. Its ability to maintain its properties under intense conditions ensures its widespread use in various industries.

Uses of Tungsten

- Light Bulb Filaments: Tungsten's high melting point makes it suitable for use in incandescent light bulb filaments, ensuring consistent performance and longevity.

- Cutting Tools: Its hardness and durability make tungsten an excellent material for manufacturing cutting tools and drill bits, enhancing efficiency and precision in industrial applications.

Steel: The Backbone of Construction

Steel is one of the most widely used metals in the world, thanks to its versatility and affordability. It can be alloyed with various elements to enhance its strength and durability, making it suitable for a wide range of applications. Its adaptability ensures its continued relevance in modern industries.

Types of Steel

- Carbon Steel: Known for its high tensile strength, carbon steel is commonly used in construction and manufacturing, providing the necessary strength and reliability for large-scale projects.

- Stainless Steel: Its resistance to corrosion makes stainless steel an ideal choice for kitchenware, appliances, and medical equipment, ensuring safety and longevity in diverse environments.

Applications of the Strongest Metals

The strongest metals find applications across various industries, from aerospace and automotive to construction and medicine. Below, we will explore some of the key applications of these metals, highlighting their significance in modern technology and infrastructure.

Aerospace Industry

The aerospace industry heavily relies on strong and lightweight metals such as titanium and aluminum alloys. These materials are used in aircraft construction to reduce weight while maintaining structural integrity, enabling efficient and safe air travel.

Construction Industry

Steel serves as the backbone of the construction industry, providing the necessary strength and durability for buildings, bridges, and infrastructure. Its affordability and versatility make it an ideal choice for large-scale projects, ensuring stability and longevity in urban development.

Comparing the Strongest Metals

Comparing the strongest metals involves evaluating their properties and determining which is best suited for specific applications. Below, we will compare titanium, tungsten, and steel based on their strength, weight, and resistance to wear, offering insights into their unique advantages and limitations.

Titanium vs. Tungsten

While titanium excels in being lighter and more corrosion-resistant, tungsten surpasses it in hardness and heat resistance. The choice between the two depends on the specific requirements of the application, balancing weight, durability, and cost-effectiveness.

Titanium vs. Steel

Titanium's strength-to-weight ratio gives it an edge over steel in applications where weight reduction is critical, such as aerospace and automotive industries. However, steel remains a more cost-effective option for many industries, ensuring affordability without compromising quality.

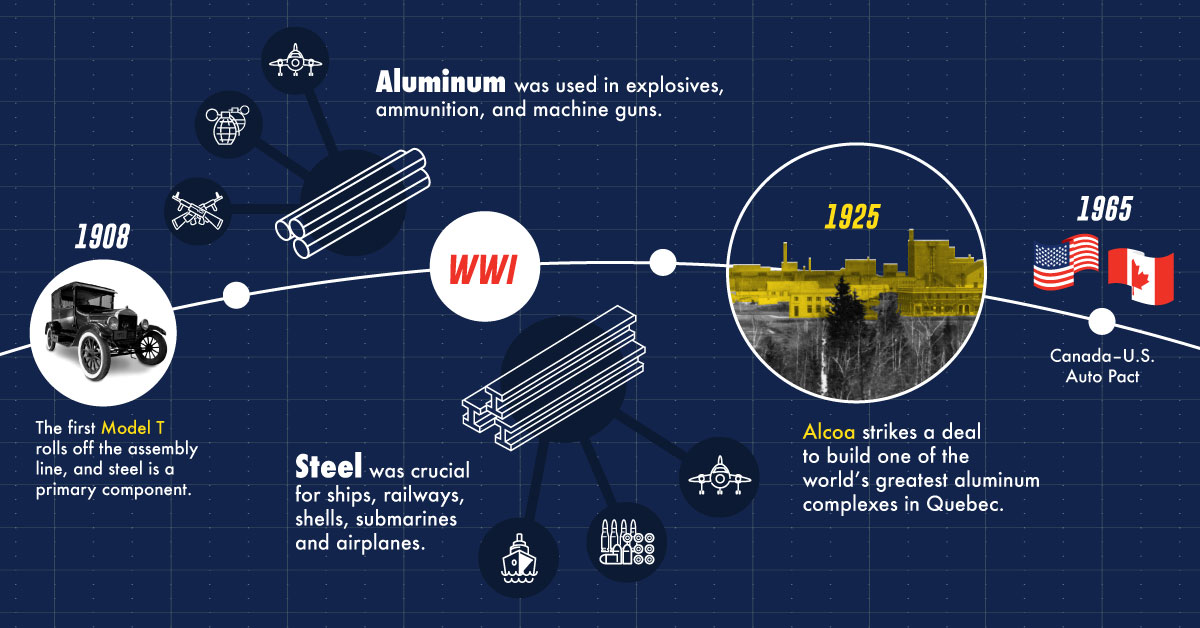

The Evolution of Strong Metals

As technology continues to advance, researchers are exploring innovative ways to enhance the strength and durability of metals. Breakthroughs in metallurgy and material science are paving the way for stronger, more versatile materials that can meet the demands of modern industries.

Emerging Technologies

- Nanotechnology: The integration of nanomaterials in metal alloys holds the potential for significant improvements in strength and durability, revolutionizing the field of metallurgy.

- 3D Printing: Advances in 3D printing technology enable the creation of complex metal structures with enhanced mechanical properties, opening new possibilities in manufacturing and design.

Conclusion

In conclusion, the strongest metal is determined by a combination of factors, including tensile strength, hardness, and resistance to wear and corrosion. Metals like titanium, tungsten, and steel each offer unique advantages that make them suitable for specific applications. By understanding the properties and applications of these metals, engineers and scientists can make informed decisions when selecting materials for their projects, ensuring optimal performance and reliability.

We encourage you to share your thoughts and questions in the comments section below. Additionally, feel free to explore other articles on our site for more insights into the world of metallurgy and materials science. Together, let's continue to expand our knowledge and push the boundaries of what is possible with the strongest metals!

Detail Author:

- Name : Miss Thalia Fadel

- Username : turner.kasandra

- Email : laverna.hoppe@bernhard.com

- Birthdate : 1997-03-30

- Address : 9081 Emile Mission South Janefurt, CT 74483-2117

- Phone : 1-341-598-4653

- Company : Funk-McGlynn

- Job : Surveying Technician

- Bio : Nihil eaque necessitatibus rerum quisquam. Molestias incidunt consequatur consequatur reprehenderit delectus et.

Socials

twitter:

- url : https://twitter.com/jimmie7567

- username : jimmie7567

- bio : Ut accusamus nostrum incidunt sit est hic. Molestiae voluptas quos commodi laborum non.

- followers : 5382

- following : 507

instagram:

- url : https://instagram.com/jimmie_id

- username : jimmie_id

- bio : Amet illum et quae. Tenetur facilis ex reprehenderit. Sit qui placeat voluptatem aut quasi quis.

- followers : 490

- following : 1546